Vat Dyes

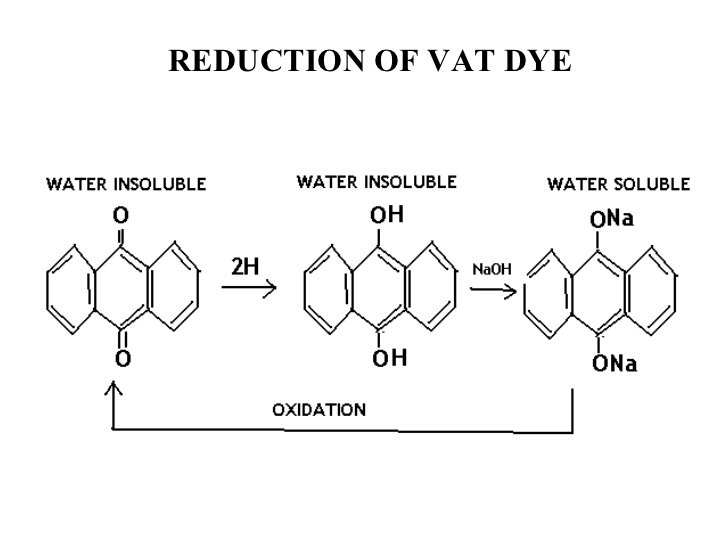

Vat dyes are a class of dyes that are classified as such because of the method by which they are applied. Vat dyeing is a process that refers to dyeing that takes place in a bucket or vat. Almost any dye, including fiber-reactive dyes, direct dyes, and acid dyes, can be used in a vat dye.

|

Vat Dyes

|

Dyeing depth(%,o.w.f)

|

C.I.No. Vat

|

Fastness

|

Dyeing method

|

||||||

|

Light(xenon)

|

Washing(95°C)

|

Rubbing

|

Perspiration

CH |

|||||||

|

Color Sample

|

Names of Vat Dyes

|

CH

|

CO

|

Dry

|

Wet

|

|||||

|

Red 6B

|

4.3

|

R13

|

7-8

|

4

|

4-5

|

3-4

|

1-2

|

4

|

IN

|

|

|

Scarlet R

|

4.0

|

R29

|

4-5

|

3-4

|

4-5

|

3-4

|

2-3

|

4

|

IW

|

|

|

Blue BC

|

5.0

|

B6

|

7-8

|

4-5

|

5

|

4-5

|

4-5

|

4-5

|

IN

|

|

|

Dark Blue VB

|

3.5

|

-

|

7-8

|

3-4

|

4-5

|

4

|

2-3

|

3-4

|

IN

|

|

|

Green GN

|

4.0

|

-

|

5

|

3-4

|

4-5

|

4

|

3

|

4

|

IN

|

|

|

Brown LG

|

4.0

|

Br23

|

4-5

|

3-4

|

4-5

|

3-4

|

2

|

3-4

|

IN

|

|

|

Black RB

|

10.0

|

BK9

|

7-8

|

3-4

|

4-5

|

3

|

2-3

|

3

|

SR II

|

|

|

Black DB

|

10.0

|

BK38

|

6-7

|

3-4

|

4

|

3-4

|

2-3

|

3

|

IN

|

|

Application of Vat Dyes

1. Procedure

1.1 Open bath

Wetting with water -> dyeing -> washing with cold water -> Oxidizing -> Washing with cold water -> Soaping -> Washing with hot water -> Washing with cold water -> Hydroextracting -> Drying.

1.2 Jig Dyeing

Wetting with water -> Dyeing -> Washing with cold water -> Oxidizing -> Soaping -> Washing with hot water -> Washing with cold water -> Drying.

1.3 Pad-steam process

Pigment padding -> Drying -> Cooling -> Chemicals liquor padding -> Steaming -> Washing with cold water -> Oxidizing -> Washing ->soaping -> Washing -> Drying.

2. Dyeing Recipes

|

Dyeing condition Amount of dyestuff (%) |

Dyeing method

|

||||||||

|

IN

|

IW

|

SR II

|

|||||||

|

0.1-1

|

1-3

|

3-6

|

0.1-1

|

1-3

|

3-6

|

0.1-1

|

1-3

|

3-6

|

|

| Caustic soda 30%(ml/l) |

10-12

|

12-17

|

17-20

|

6-8

|

8-12

|

12-14

|

22-25

|

25-32

|

32-38

|

| Hydrosulphite 85%(g/l) |

4-5

|

5-7

|

7-8

|

3.5-4.5

|

4.5-6.5

|

6.5-7

|

4-5

|

5-7

|

7-8

|

| Wetting agent 10%(ml/l) |

5

|

5

|

5

|

5

|

5

|

5

|

5

|

5

|

5

|

| Alcohol 95%(ml/l) |

5

|

5

|

5

|

5

|

5

|

5

|

5

|

5

|

5

|

| Sodium sulfate anhydrous (g/l) |

-

|

-

|

-

|

5-10

|

10-15

|

15-25

|

-

|

-

|

-

|

| Reduction temp. (°C) |

60

|

50

|

60

|

||||||

| Dyeing temp. (°C) |

60

|

45-50

|

80

|

||||||

3. Pad-steaming recipes

|

Dyeing method

|

Dyeing depth

|

Caustic soda (g/l) |

Hydrasulphite

85% (g/l) |

Common salt of Sodium sulfate

(g/l) |

Steaming time

(secs) |

Steam temp.

(°C) |

|

Pad-steam

|

Pale-Medium

|

10-30

|

10-30

|

20-30

|

30-60

|

102-104

|

|

Medium-Deep

|

30-40

|

30-40

|

30-40

|

4. Stock Vat Recipe

|

Process

|

SVI

|

SVII

|

SVIII

|

|

Liquor ratio

|

1:50

|

1:50

|

1:100

|

|

Caustic soda 30% (g/l)

|

60

|

30

|

60

|

|

Hydrosulphite 85% (g/l)

|

15

|

10

|

15

|

|

Vatting temp. (°C)

|

60

|

50

|

60

|

|

Vatting time (min)

|

10-15

|

10-15

|

10-15

|

5. Oxidizing both Recipe

|

Method

|

Sodium Perborate

|

Hydrogen peroxide 30%

|

Potassium(sodium bichromate)

|

|

Amount

|

3-4g/l

|

2-3ml/l

|

1-2g/l

|

|

Glacial acetic acid

|

-

|

-

|

1-2ml/l

|

|

pH

|

10-11

|

9-10

|

-

|

|

Temp. (°C)

|

40-50

|

20-40

|

30-40

|

|

Time (min)

|

10-20

|

10-20

|

10-20

|

6. Soaping Bath Recipe

Soap: 3-5g/l

Sodium carbonate: 2-3g/l

Temp: 98-100°C

Time (min): 10-12

Remark:the above recommendations concerning to the use of our products should be modified, if necessary to conform with local conditions and materials used.

VAT RED F3B

Matching Product for Reference

| Dyeing Depth |

Fabric specification 40sX 40s 133X72 |

Dyeing Durability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solarization | Soaping (95°C) | Sweat stains (acid) | Sweat stains] (alkali) | Ironing | Rubbing | Chlorine bleach | ||||||

|

/

|

Original sample

change |

Calico

colouring |

Original sample

change |

Calico

colouring |

Original sample

change |

Calico

colouring |

/

|

Dry

|

Wet

|

/

|

||

|

6-7

|

4-5

|

4-5

|

4-5

|

4-5

|

4-5

|

4-5

|

4

|

4

|

3

|

4

|

||

National standard of P.R.C.: Testing method of vat dyes color and durability: according to GB2377-80

Products testing method:

Dyeing method:

Dyeing conditions

| Dyeing depth(dye volume is calculated on fabric volume) |

%

|

0.1-1

|

1-3

|

3-6

|

| 30% sodium hydroxide |

m/l

|

6-8

|

8-12

|

12-14

|

| 85% sodium hydrosulfite |

g/l

|

3.5-4.5

|

4.5-6.5

|

6.5-7

|

| 10% penetrant |

m/l

|

5

|

5

|

5

|

| 95% ethanol |

m/l

|

5

|

5

|

5

|

| Anhydrous sodium sulfate |

g/l

|

5-10

|

10-15

|

15-20

|

| Reduction temperature |

°C

|

50

|

/

|

|

| Dyeing temperature |

°C

|

4.5-50

|

/

|

|

Technical process of dyeing

1. Exhaust dyeing

Dyeing -Cool rinsing -Oxidation-Cool rinsing-Soaping -Hot rinsing-Cool rinsing-Dehydration-Drying

2. Jig dyeing

Dyeing-Rinsing-Oxidation-Soap boiling-Hot rinsing-Cool rinsing-Drying

3. Pad-steam process

pad dyeing -Drying-Cooling in the air-Pad chemical liquor-Steam-Cool rinsing-Oxidation-Rinsing-Soap boiling-Rinsing-Drying

|

VAT DYES

|

Dyeing

Depth(%) |

Fastness

|

Dyeing

method |

||||||

|

Colour |

Names of

Vat Dyes |

Light

(Xenon) |

Washing

(95°C) |

Rubbing

|

Perspiration

|

||||

|

CH

|

CO

|

Dry

|

Wet

|

||||||

|

Or 1

|

2.0

|

6-7

|

4-5

|

4

|

4

|

3

|

4-5

|

IK

|

|

|

Or 9

|

2.0

|

5-6

|

4-5

|

5

|

4-5

|

4

|

4-5

|

IN

|

|

|

Or 2

|

3.0

|

5

|

4-5

|

4-5

|

4-5

|

3-4

|

4-5

|

IN

|

|

|

Or 7

|

3.0

|

6-7

|

5

|

5

|

4-5

|

3-4

|

4-5

|

IN

|

|

|

R 15

|

4.0

|

6-7

|

4-5

|

4-5

|

4-5

|

3-4

|

4

|

IN

|

|

|

Br 72

|

3.0

|

6

|

4

|

4-5

|

4-5

|

3-4

|

4

|

IN

|

|

|

Br 3

|

3.0

|

7-8

|

5

|

5

|

4-5

|

4-5

|

4

|

IN

|

|

|

Br68

|

3.0

|

5

|

3-4

|

4-5

|

4

|

3-4

|

3-4

|

IN

|

|

|

Br 1

|

3.0

|

7-8

|

5

|

5

|

4-5

|

3-4

|

4-5

|

IN

|

|

|

Bk 25

|

3.0

|

7-8

|

4-5

|

4-5

|

4

|

3

|

4

|

IN

|

|

|

G 3

|

3.0

|

7-8

|

4

|

4-5

|

4

|

3-4

|

4

|

IN

|

|

|

G 13

|

3.0

|

7-8

|

4-5

|

5

|

|

|

|

IN

|

|

|

G 1

|

3.0

|

7-8

|

4-5

|

5

|

4-5

|

4

|

5

|

IN

|

|

|

G 8

|

3.0

|

7-8

|

5

|

5

|

4-5

|

2-3

|

4-5

|

IN

|

|

|

V 1

|

2.0

|

6

|

4-5

|

4-5

|

4-5

|

4

|

4-5

|

IN

|

|

|

V 9

|

3.0

|

6

|

4-5

|

5

|

4-5

|

4

|

4-5

|

IN

|

|

|

B 20

|

4.0

|

7-8

|

4-5

|

5

|

4-5

|

2

|

4-5

|

IN

|

|

|

B VB

|

3.5

|

7-8

|

3-4

|

4-5

|

4

|

2-3

|

3-4

|

IN

|

|

|

B 4

|

3.5

|

7-8

|

4-5

|

5

|

4

|

3

|

4-5

|

IN

|

|

|

B

|

4.0

|

6

|

3-4

|

3-4

|

4

|

3

|

4

|

IN

|

|

|

Bk 29

|

2.0

|

6-7

|

4-5

|

5

|

|

|

|

IN

|

|

|

Bk 16

|

2.0

|

6-7

|

4.R

|

4-5

|

|

|

4-5

|

IN

|

|

|

Bk 8

|

4.0

|

7-8

|

4-5

|

5

|

4-5

|

4-5

|

4-5

|

IN

|

|

|

Bk

|

10.0

|

6

|

3-4

|

3-4

|

4

|

3

|

4

|

IN

|

|

Dyestuffs

Affiliates

-

Everlight Chemiecolor

Supplier for Soap Making Materials -

Miralyn Construction

Hardware and Construction Supplies