Reactive Dyes

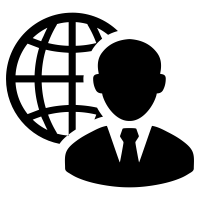

Reactive dye is the dye that can react with a fibre to form a covalent link, that is forming a permanent attachment in the fibre and could not be removed by repeated treatment with boiling water under neutral conditions.

Reactive dyes are most commonly used in dyeing of cellulose like cotton or flax, but also wool is dyeable with reactive dyes. Reactive dyeing is the most important method for the coloration of cellulosic fibres. Reactive dyes can also be applied on wool and nylon; in the latter case they are applied under weakly acidic conditions.

K Type

|

Reactive Dyes

|

Dyeing

Depth % o.w.p.

|

Fastness

|

Solubility

50°C g/l |

|||||||

|

Light

(xe arc)

|

Soaping

95°C |

Perspiration

(Al, AC) |

Rubbing

(W, D) |

Hot

pressing 200°C

|

||||||

|

Name

of Dyes

|

C.I

|

Colour

Sample

|

CH

|

CO

|

||||||

|

Reactive

Brill Yellow K-6G

|

R.Y.2

|

|

3

|

5

|

4

|

4-5

|

4

4-5 |

4-5

4-5 |

4-5

|

≥ 50

|

|

Reactive

Yellow K-RN

|

R.Y.3

|

|

3

|

6

|

4-5

|

4-5

|

4-5

4-5 |

4-5

4-5 |

4-4

|

≥ 40

|

|

Reactive

Brill Orange K-GN

|

R.0.5

|

|

3

|

5

|

4

|

4-5

|

4-5

4-5 |

4-5

3-4 |

4-5

|

≥ 50

|

|

Reactive

Red K-2G

|

R.R.15

|

|

3

|

5-6

|

4-5

|

4-5

|

4

4-5 |

4-5

3 |

4-5

4 |

≥ 100

|

|

Reactive

Red K-2BP

|

R.R.24

|

|

3

|

5-6

|

3-4

|

4-5

|

4

3-4 |

4-5

3-4 |

4

|

≥ 100

|

|

Reactive

Violet K-3R

|

R.V.2

|

|

3

|

6

|

4-5

|

5

|

4-5

5 |

4

3 |

4-5

5 |

≥ 100

|

|

Reactive

Red Brown K-B3R

|

R.B.9

|

|

3

|

4-5

|

4-5

|

4-5

|

4-5

5 |

4

2-3 |

4-5

|

≥ 50

|

|

Reactive

Brill Blue K-GR

|

R.R.5

|

|

4

|

4-5

|

4-5

|

5

|

5

4-5 |

5

4-5 |

4-5

|

≥ 30

|

|

Reactive

Turgoise Blue K-GL

|

R.B.14

|

|

4

|

6-7

|

3-4

|

4-5

|

4-5

4-5 |

4-5

4 |

4-5

|

≥ 130

|

|

Reactive

Brill Blue P-3R

|

R.B.49

|

|

4

|

5-6

|

4

|

4-5

|

4

4-5 |

4-5

4 |

4-5

|

≥ 100

|

|

Reactive

Blue K-R

|

R.B.13

|

|

3

|

6-8

|

4-5

|

4

|

4

4 |

4-5

3-4 |

4-5

|

≥ 60

|

|

Reactive

Black K-BR

|

R.B.8

|

|

4

|

6

|

3-4

|

4-5

|

4-5

4 |

4

2-3 |

4-5

|

≥ 20

|

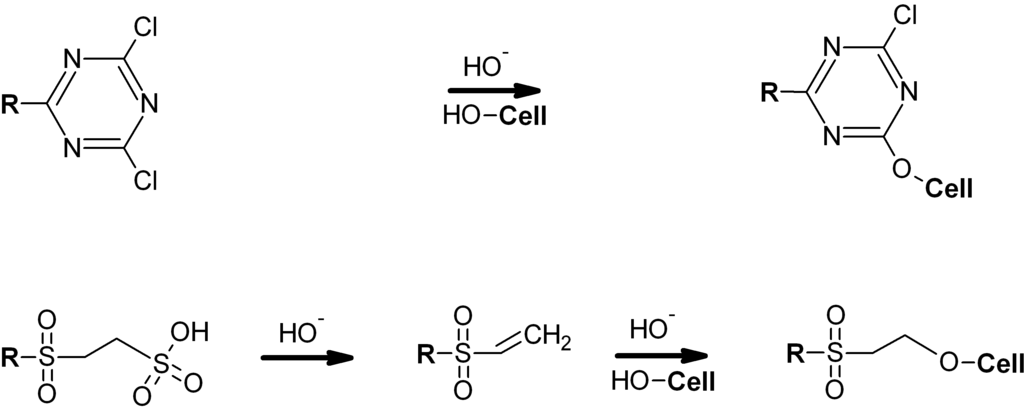

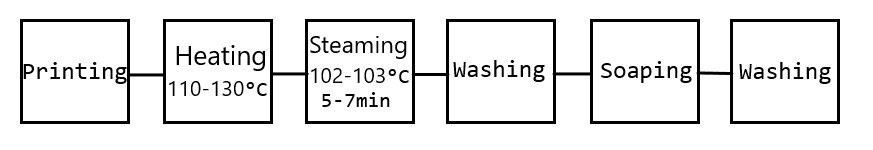

1. Printing Method

Process

Recipe

|

Dyestuff

|

Heat

water

|

Urea

|

Sodium

alaginate

|

Reduction Inhibitor

|

NaHCO3

|

Total

|

|

0.5

5 |

X

|

1

5 |

20

40 |

1

|

1

5 |

100

|

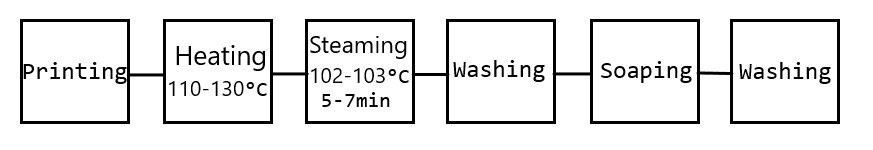

2. Dyeing Method

Process

|

Recipe

KN Type

|

|

Dyeing

Depth % o.w.p.

|

Fastness

|

Solubility

50°C g/l |

|||||||

|

Light

(xe arc) |

Soaping

95°C

|

Perspiration

(Al, AC) |

Rubbing

(W, D)

|

Hot

pressing 200°C

|

||||||

|

Name

of Dyes

|

> C.I

|

Colour

Sample

|

CH

|

CO

|

||||||

|

Reactive

Orange KN-2G

|

R.O.72

|

|

3

|

5-6

|

5

|

5

|

5

5 |

4-5

4 |

4-5

|

≥ 300

|

|

Reactive

Orange KN-GR

|

|

2

|

4-5

|

5

|

5

|

5

5 |

4-5

4 |

4-5

|

≥ 120

|

|

|

Reactive

Orange KN-5R

|

R.0.16

|

|

3

|

5-6

|

4

|

4-5

|

4-5

4-5 |

4-5

3-4 |

4-5

|

≥ 40

|

|

Reactive

Turquoise Bluekn KN-G

|

R.B.21

|

|

4

|

6-7

|

3-4

|

4

|

4

5 |

4

4-5 |

4-5

|

≥ 100

|

|

Reactive Brill Blue KN-R

|

R.R.19

|

|

3

|

5

|

4

|

3-4

|

5

4 |

4

2-3 |

4-5

|

≥ 100

|

|

Reactive

Myrtle KN-2BR

|

|

2

|

3-4

|

4-5

|

3

|

5

4 |

4-5

4-5 |

4

|

≥ 100

|

|

|

Reactive

Violet KN-4R

|

R.V.5

|

|

4

|

6

|

4

|

4-5

|

4-5

4-5 |

4-5

4-5 |

4-5

4-5 |

≥ 80

|

|

Reactive

Black N150

|

|

|

4

|

4-5

|

4

|

4-5

|

4

4 |

4-5

4-5 |

4-5

4-5 |

≥ 300

|

|

Reactive

Black KN-B

|

R.B.5

|

|

4

|

4-5

|

4

|

4-5

|

4

4 |

4-5

4-5 |

4

|

≥ 300

|

|

Reactive

Black KN-G2RC

|

|

4

|

4-5

|

4

|

4-5

|

4

4 |

4-5

4-5 |

4

|

≥ 200

|

|

|

Reactive

Black KN-2R

|

|

4

|

4-5

|

4

|

4-5

|

4

4 |

4-5

4-5 |

4

|

≥ 200

|

|

1. Printing Method

Process

Recipe

|

Dyestuff

|

Heat

water

|

Urea

|

Sodium

alaginate

|

Reduction Inhibitor

|

Na2HPO4

|

CCI3COONa

|

Total

|

|

0.5

5 |

X

|

1-10

|

20

40 |

1

|

0.5

1 |

3-6

|

100

|

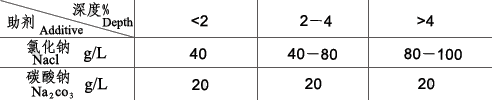

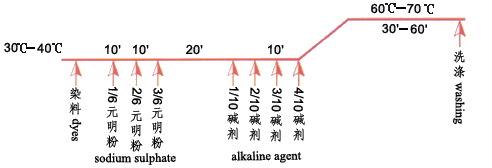

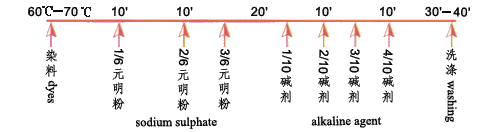

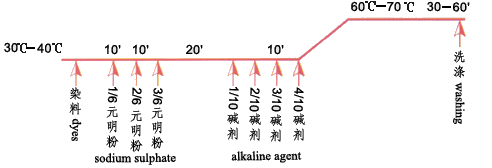

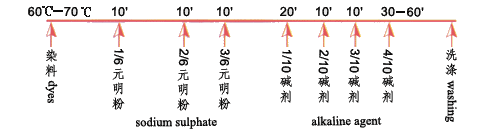

Temperature Raising Method

Constant Temperature Method

Recipe

M Type

|

|

Fastness |

Solubility

50°C g/l |

||||||||

|

Light

(xe arc) |

Soaping

95°C

|

Perspiration

(Al, AC) |

Rubbing

(W, D)

|

Hot

pressing 200°C

|

||||||

|

Name

of Dyes

|

>C.I

|

Colour

Sample

|

CH

|

CO

|

||||||

|

Reactive

Brill Yellow M-3G

|

|

|

3

|

5

|

3-4

|

4

|

4

3-4 |

4

4 |

4

|

≥ 100

|

|

Reactive

Yellow M-5R

|

|

2

|

6-7

|

4-5

|

4-5

|

4

4-5 |

4-5

4 |

4

|

≥ 100

|

|

|

Reactive

Yellow M-3RE

|

R.Y.145

|

|

2

|

6-7

|

5

|

4-5

|

5

5 |

4-5

4 |

4

|

≥ 100

|

|

Reactive

Brill Orange M-3R

|

|

2

|

5

|

3-4

|

4

|

4

3-4 |

4

4 |

4

|

≥ 100

|

|

|

Reactive

Brill Orange M-2GR

|

|

2

|

6

|

5

|

4-5

|

4-5

|

4

|

4

|

≥ 100

|

|

|

Reactive

cochineal M-3G

|

|

2

|

5-6

|

4-5

|

5

|

4-5

4-5 |

4-5

4-5 |

4

|

≥ 100

|

|

|

Reactive

Red M-2B

|

R.R.194

|

|

2

|

5-6

|

4-5

|

5

|

4-5

4-5 |

4-5

4-5 |

4

|

≥ 100

|

|

Reactive

Red M-3BE

|

R.R.195

|

|

2

|

5-6

|

4-5

|

5

|

4

3-4 |

4-5

4 |

4

|

≥ 100

|

|

Reactive

Red M-8B

|

|

2

|

5

|

4

|

4-5

|

4

4-5 |

4-5

4 |

4

|

≥ 100

|

Reactive

Red M-6BF

|

R.R.250

|

|

2

|

5

|

4-5

|

4-5

|

4

4 |

4-5

4 |

4

|

≥ 100

|

|

Reactive

cochineal M-4BD

|

|

2

|

5

|

4-5

|

4-5

|

4

4 |

4-5

4 |

4

|

≥ 100

|

|

|

Reactive

Violet M-R

|

|

2

|

3-4

|

4

|

4

|

4

4 |

4

4 |

4

|

≥ 100

|

|

|

Reactive

Brill Blue M-BR

|

|

3

|

5

|

4

|

3-5

|

4

4-5 |

4-5

4-5 |

4

|

≥ 60

|

|

|

Reactive

Blue M-R

|

|

3

|

5-6

|

3-4

|

4-5

|

3-4

|

4-5

4 |

4

|

≥ 80

|

|

|

Reactive

Blue M-2GE

|

R.B.194

|

|

2

|

6-7

|

4

|

4-5

|

4

4-5 |

4-5

4 |

4-5

|

≥ 100

|

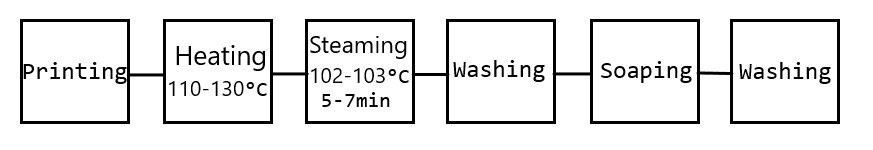

1. Printing Method

Process

Recipe

|

Dyestuff

|

Heat

water

|

Urea

|

Sodium

alaginate

|

Reduction Inhibitor

|

NaHCO3

|

Total

|

|

0.5

5 |

X

|

1

5 |

20

40 |

1

|

1

3 |

100

|

Temperature Raising Method

Constant Temperature Method

Recipe

Dyestuffs

Affiliates

-

Everlight Chemiecolor

Supplier for Soap Making Materials -

Miralyn Construction

Hardware and Construction Supplies